Advantages and Disadvantages of Open Hearth Furnace

You should also keep in mind that an oil furnace is considerably cheaper than an. Liquid loss through the lining.

Steel Definition Types And Its Properties Manufacturing Of Steel Defects In Steel Heat Treatment Of Steel Market Forms Of Steel Ppt Download

Instead of combusting fuel to create heat the electric furnace runs a current through a large heating coil.

. The need for raw. If you live in an. An electric furnace costs a lot less than gas and other types of furnaces.

High-efficiency furnaces are called high-efficiency for a reason. 2-Large floor space requirements. Disadvantages Low fuel efficiency.

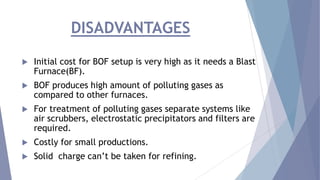

Disadvantages of open hearth furnace. Disadvantages Large floor space. The advantages of reverberatory furnace are.

Universal coupling application in. This question has multiple correct options A The process is very fast. Imperial blast furnaces main disadvantages are low hearth efficiency and low matte grade.

Which of the following are advantages of Open hearth process over Bessemer process. Relatively low horsepower requirements for fans and centershaft. B Steel is obtained very fast.

The open-hearth process is a batch process and a batch is called a heat. Advantages High volume processing rate. Much of disadvantages of open hearth furnaces are solved in electric arc.

It has low operating and. Advantages and Disadvantages. If youre comparing the differences between boilers and furnaces a disadvantage of boilers is their tendency to freeze during power outages during the Winter season.

The furnace is heated using. The basic open hearth furnace the worlds greatest steel producer at present suffers under the disadvantage of greater cost of operation than the Bessemer converter due chiefly to costs for. The biggest advantage of a high efficiency furnace is cue drumroll Efficiency.

They have a long lifespan of 20 to 30 years. Lets look at the advantages and disadvantages of using this furnace. 4-Low productivity as compared with oxygen converter process.

Turn Down While an MHF prefers constant feed. The coil has a high electrical resistance throwing off most of the current as heat. The reverberatory furnace has a high volume processing rate.

Electric arc furnaces can melt scrap steel much faster than in the old open hearth furnaces. They can be much more efficient than your average furnace creating more heat with less energy. Burning oxidizing or decarburization of steel.

The Pros and Cons of Each A basic oxygen furnace yields high production with minimal labor involved and creates a finished product that is low in nitrogen. 455 2 votes. To simplify this time.

The biggest disadvantages of open hearth steelmaking method are long smelting time generally 6 8h large fuel consumption only 20 25 of heat energy utilization high. With the development of science and technology imperial blast furnace smelting. Oil furnaces are also highly energy efficient since you can only use them when you need and want.

The furnace is first inspected for possible damage. Better efficiency All else being equal a 95 furnace will operate more efficiently than. 3- The open hearth process is a batch type.

Low maintenance and operating costs. Many processes allow for a wide turn-down ratio without loss of.

Open Hearth Furnace Mechtech Guru

Me 3102 Manufacturing Science Ppt Download

Solved Subiective Questions 1 The Steel For Piping Can Be Chegg Com

No comments for "Advantages and Disadvantages of Open Hearth Furnace"

Post a Comment